Why are some instruments and effects still operating after 30 years? Maybe the design was well thought and the craftsmanship good? I think so.

It all start with the design. It does not matter how good you are to assemble a box if the design is bad. So, how make a robust design?

There are some points that I will bring out in that matter;

- Think of the worst case scenario

- Use parts that can handle the physical stress

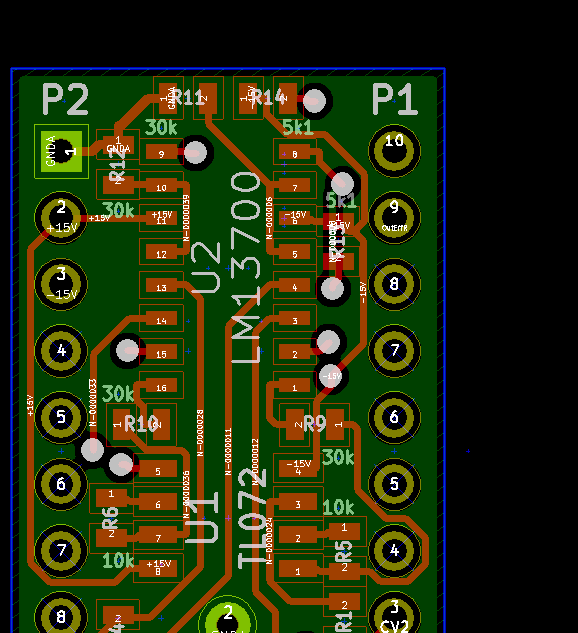

- Design for manufacturing (DFM)

- Add margins to your design

- Manufacture the products after rigid standards

- If possible, add self correcting functions if a fault occur

- Test the products good before they are sold

But where to start with all this?

Wee, there are a LOT of articles written about this already. Just search “DFM” on google and take a look. You will find tips and rules on how to make electronics that is possible to produce in the best manner. I would like to point out the IPC standard. That is common standards describing everything from the layout of a board to how to mount it in a factory.  Why is that important to have standards for this? Because you can refer to them and you don’t have to write all the specs on how the production of your design should be done. It is a well thought common frame for both the designer and the producer. That is why it is important that the designer of the circuits is familiar with this. Øyvind Mjanger is a certified PCB designer (CID). Good.

Why is that important to have standards for this? Because you can refer to them and you don’t have to write all the specs on how the production of your design should be done. It is a well thought common frame for both the designer and the producer. That is why it is important that the designer of the circuits is familiar with this. Øyvind Mjanger is a certified PCB designer (CID). Good.

You should also know how to produce electronics in a factory. That requires experience from the field. Then you know how to place parts so they don’t collide with the machines during production. And so on.